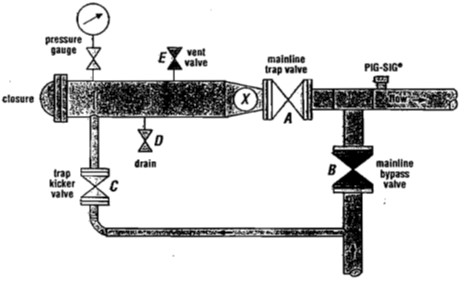

Pig Launching and Receiving Procedure For Liquid Service

Pig Launching

1. Close Valves A and C

2. Drain the launching trap by opening drain Valve D and allow air to displace the liquid by opening vent valve E.

3. When the trap is completely drain (0 psig) with Valves E and D still open, open the closure door and insert the pig so the first cup forms a tight fit in the reducer at point X.

4. Close and secure the closure door. Close drain Valve D and leave vent Valve E open . Slowly fill the trap through Valve C by venting the air through Valve E. When filling is completed close vent Valve E to allow pressure to equalize then close Valve C.

5. Open Valve A first and then open Valve C. The pig is now ready for launching.

6. Partially close Valve B. This will increase the flow of liquid through Valve C and behind the pig. Continue to close Valve B until the pig moves out of the trap into mainline stream as signaled by the PIG-SIG indicator.

7. When the pig leaves the trap and enters the mainline, open Valve B fully.

Pig Launcher For Liquid Service

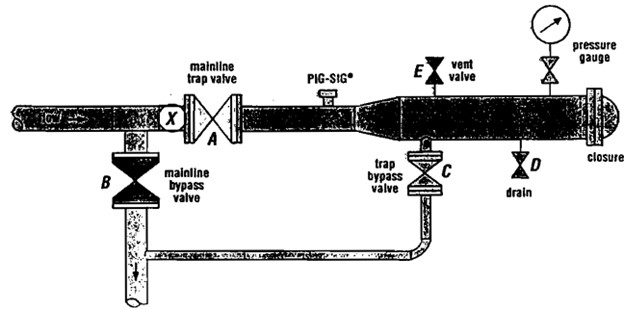

Pig Receiving

1. Close drain Valve D. Slowly fill the trap by opening Valve C venting through Valve E.

2. Close vent Valve E to allow trap pressure to equalize through Valve C.

3. With valve C open, open Valve A. Trap is now ready to receive pig.

4. When the pig arrives it may stop between trap Valve A and the tee (point X)

5. Partially close Valve B. This will force the pig into the trap due to increasing flow through Valve C.

6. When the pig is in the trap as signaled by the PIG-SIG indicator open Valve B completely and close Valves A and C.

7. Open drain Valve D and vent Valve E and drain the trap.

8. After the trap is fully drained (0 psig) with Valves D and E still open, open the closure door and remove the pig.

9. Close and secure the closure door.

Pig Receiver For Liquid Service

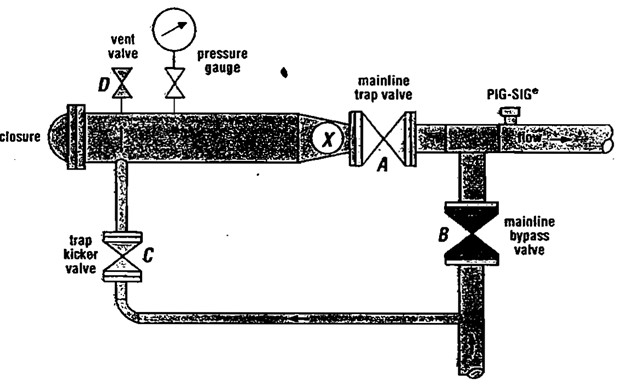

Pig Launching and Receiving Procedure For Gas Service

Pig Launching

1. Close Valves A and C

2. Open Valve D to vent launching trap to atmospheric pressure.

3. When the trap is completely drain (0 psig) with Valves D still open, open the closure door and insert the pig so the first cup forms a tight fit in the reducer (point X)

4. Close and secure the closure door. Purge air from trap through Valve D by slowly fill the trap through Valve C. When purge is completed close Valve D to allow pressure to equalize. Then close Valve C.

5. Open Valve A then Valve C. The pig is now ready for launching.

6. Partially close Valve B. This will force increasing gas flow through Valve C and behind the pig. Continue to close Valve B until the pig moves out of the trap into mainline stream as signaled by the PIG-SIG indicator.

7. When the pig leaves the trap and enters the mainline, open Valve B fully.

Pig launcher for gas service

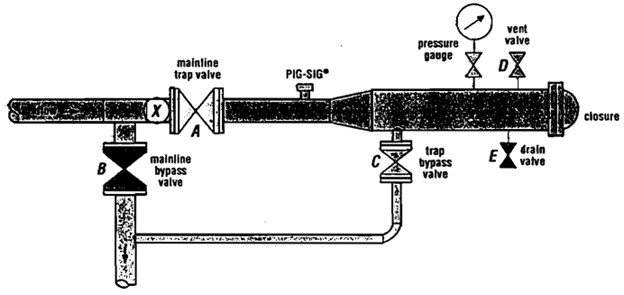

Pig Receiving

1. To purge the trap, close Valve B and slowly open Valve C.

2. After purging, allow the trap pressure to equalize by closing Valve B with Valve C open.

3. With Valve C open still open, open Valve A. The trap is now ready to receive the pig.

4. When the pig arrives it may stop between trap Valve A and the tee (point X )

5. Partially close Valve B. This will force the pig into the trap due to increasing flow through Valve C.

6. After the pig is in the trap as signaled by the PIG-SIG indicator open Valve B and close Valves A and C.

7. Open drain Valves D and E and vent the trap to atmospheric pressure.

8. After the trap is vented (0 psig) and drained with Valves D and E open, open the closure door and remove the pig.

9. Close and secure the closure door.

Pig receiver for gas service

கருத்துகள் இல்லை:

கருத்துரையிடுக